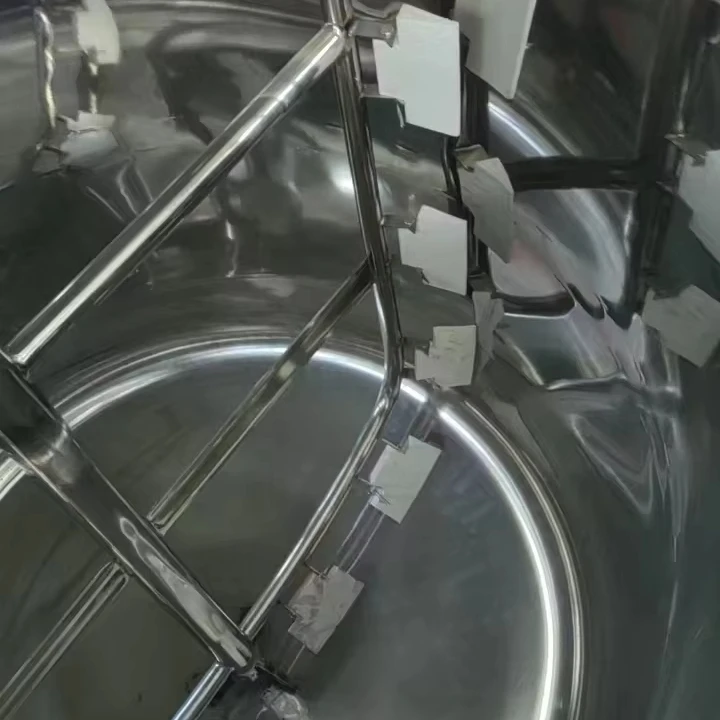

Food Grade Stainless Steel Tank With Agitator

Other recommendations

Overview

Food Grade Stainless Steel Tank With Agitator

Technical parameters:

|

Work Volume |

Dimension of tank |

Total height |

Insulated layer |

Diameter of inlet&outlet |

|

(L) |

(mmxmm) |

(mm) |

(mm) |

(mm) |

|

500 |

840*1000 |

2300 |

60 |

38 |

|

600 |

920*1000 |

2400 |

60 |

38 |

|

700 |

990*1000 |

2400 |

60 |

38 |

|

800 |

950*1220 |

2550 |

60 |

38 |

|

900 |

1010*1220 |

2700 |

60 |

38 |

|

1000 |

1060*1220 |

2700 |

60 |

51 |

|

2000 |

1340*1500 |

2750 |

60 |

51 |

|

3000 |

1410*2000 |

3500 |

60 |

51 |

|

5000 |

1910*2000 |

3850 |

60 |

51 |

|

10000 |

2300*2440 |

4500 |

60 |

51 |

|

15000 |

2530*3000 |

5200 |

60 |

51 |

|

20000 |

2640*3660 |

5800 |

60 |

51 |

'

It is widely used in paint, medicine, building materials, chemical industry, pigments, resins, food, scientific research and other industries. The equipment can be made of carbon steel, stainless steel and other materials according to the technological requirements of users'products, and set up heating and cooling devices to meet different technological and production needs. The heating form includes jacket electric heating and coil heating. The equipment has reasonable structure design, advanced technology, durable, simple operation and convenient use. It is an ideal equipment with less investment, fast commissioning and high profit.

- Tel:

-

Email:

Certifications

SUBSCRIBE

INQUIRY