Stainless Steel Industrial Powder Mixer

Other recommendations

Key attributes

Industry-specific attributes

3500

50 L

Other attributes

Agitator

Chemicals, Food

100 KG

New

Zhejiang, China

2.2 kW

1 year

Automatic

Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

None

Ordinary Product

Provided

Provided

1 Year

Bearing

0 - 2840 r.p.m

15Tons

SUS304, SUS316

Detergent Powder

Liquid with Suspended Solids

Milling

VINCE

380V/50HZ, 220V/60HZ, 3P or customized

Based on actual volumn

Overseas third-party support available

Stainless Steel/SS304

Mixer

Packaging and delivery

wooden case packing

Single item

60X50X40 cm

50.000 kg

Customization

Customized logo

Min. order: 5

Customized packaging

Min. order: 5

Graphic customization

Min. order: 5

Overview

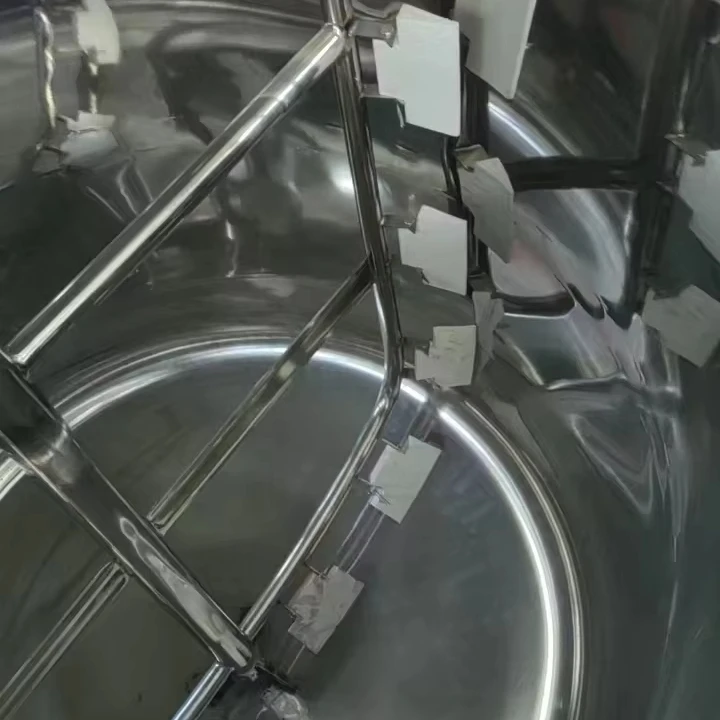

Stainless Steel Industrial Powder Mixer

Specifications

inline liquid and powder mixer

1. liquid powder mixer

2. water-powder mixer

3. 5T-20T/H water powder mixer

Product Name:Liquid Powder Mixer

Material :304(L) 316(L) Finish:Mirror or Matt Polish; Ra<0.4um Certification:CE ISO9001

Working Method:

The Liquid Powder Mixer is composed of a casing and a mixing pump which consists of rotor and stator, are mounted vertically. the suction side has a double- wall tube that keeps the inlet of solids separate from the liquids, Thus avoiding the formation of clots before the material enters the casing The liquid enters the mixing chamber at a high velocity, Thereby creating a vacuum in the center of the mixing pump gear, which causes the suction of solids. The fall of the solids could be regulated by means of a valve situated at the bottom of the hopper.

Application:

The products could be applied in food, beverage, Pharmacy, chemical industry etc.

such as mixing power milk into water

1. Q: How do I pay for my purchase order?

A: T/T, L/C at sight, Escrow, Paypal.

2. Q: What's the MOQ?

A: Our MOQ is 1 unit.

3. Q:What's the delivery time?

A: It will take about 25-35days to finish an order, but the exact time is according to actual situation.

4. Q: Can I have my own customized product?

A: Yes, your customized requirements for color, logo, design, mark, etc. are very welcome.

5. Q: Do you have quality control?

A: Yes, we attach great performance to quality control.

6. Q: How about the warranty control?

A: One year warranty for the machineries since sold. If quality problem occurs, please feel free to contact us.

- Tel:

-

Email:

Certifications

SUBSCRIBE

INQUIRY